|

Abstract:

The use of biomaterials is continuously increasing in daily

orthopaedic practice. New materials are introduced in order to

combine as many as possible favourable properties in one and

only material. Porous tantalum has unique characteristics. Its

elasticity is close to subchondral bone, while at the same time

it is highly adherent. It has a great porosity of up to 80% of

its total volume which promotes osteointegration. It can be

constructed in a variety of sizes and shapes that allows its

application in many areas of orthopaedic surgery.

J.Orthopaedics 2009;6(4)e3

Keywords:

porous tantalum;

interface;

acetabular implant

Introduction:

During the

last 25 years various biomaterials and porous surfaces have been

used in the area of reconstructive orthopaedic surgery, in order

to achieve osteo-integration

of the implants. Clinical and histological data from removed

parts of arthroplasties advocate that porous surfaces reinforce

the implant’s stability via biological integration procedures.

However, the most common used materials, titanium and

cobalt-chromium alloy, can’t respond to the demanding mechanical

status of orthopaedic implants because of their mechanical

features. This is the reason why they are used only as modes of

superficial coating, while the implant’s supporting structure is

made from another compact metal. Also, the rate of porous

texture of these coatings is about 30%-50% of their total volume

and this restricts their ability of bony penetration. The latter

is proportional to the amount of pores, expressed as percentage

of the total volume of the material1-3. In the area

of structural grafts at the same time, a large number of

synthetic biomaterials have been introduced and significant

improvements in use of bone allografts have been made. The

purpose of all these is the restoration of bone deficit areas

with simultaneous bone penetration and integration. The

biomaterial’s ability to succeed this, depends mainly on the

porous texture, the mechanical resistance, both short and long

term, the elasticity (which ideally should approach the

elasticity of cancellous bone), the resistance to absorption,

the immune inactivity and the ease of manufacturing and use. It

is obvious that the combination of a high ratio of porous

texture, with the appropriate mechanical properties for use in

orthopaedic surgery in one and only biomaterial is particularly

desirable.

Properties of pure tantalum

Pure tantalum (ASTM F-560) is a highly biocompatible material

which does not provoke cellular reactions as other materials

like nickel, cobalt and chromium4,5 do. It is a hard

metal which resists in oxidation, corrosion and concomitant ion

production6. Tantalum is being used for over 50 years

as an implant in humans, in a variety of applications:

electrodes for pacemakers7, plates for cranioplasty8

, clips for ligation9 , femoral stems10,

wires, nets or plates in nerve surgery11 and as a

medium of marking in radiological studies for implant migration12.

The property of tantalum to adhere to bone, possibly via a not

well elucidated chemical connection procedure, is known for many

years, mainly through the application of tantalum in the area of

dental implantation13. Historically, only the pure

titanium and tantalum have this property that also newer

biomaterials (CaHAP, crystalloids, hyaloids) have. According to

Kokubo et al14, after the exposition of tantalum in

body moist, a superficial layer of sodium tantalum is created,

ions of Na+ are released from this and connections of

tantalum with hydroxyl roots are made (Ta-OH). The latter are

connected with free Ca ions (Ca++) and thus amorphous

calcium tantalum is created (Calcium Tantalate). The combination

of calcium tantalum with phosphorus ions leads to amorphous

phosphoric calcium, which is converted to hydroxyapatite. In

this way, a solid connection between bone and metal is achieved.

Recently, Findlay and Whelldon15,16 tested the

ability of polished tantalum to support the growth and function

of normal human osteoblastic cells, in comparison with other

substrates and specifically titanium and chromium-cobalt (that

have proved in clinical practice their ability for bony

integration). They studied the number and morphology of adherent

osteoblasts with electronic microscopy and their rate of

proliferation and biological activity, expressed via mRNA

concentrations. They concluded that pure tantalum is at least

the same effective with the above mentioned biomaterials as a

substrate for adhesion, growth, differentiation and function of

human osteoblasts.

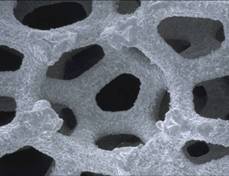

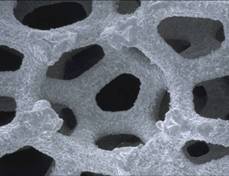

Porous tantalum preparation and

properties

Porous tantalum is a new biomaterial, which was constructed a

decade ago17,18. Preparation of porous tantalum

starts with polyurethane’s foam pyrolysis (thermal conversion).

This foam turns to a skeleton of low density hyaloid carbon,

with a characteristic repeated duodenofundament structure that

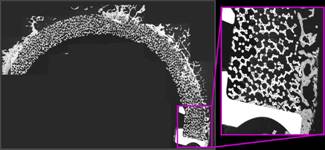

leads to pores connected with smaller holes (Fig 1). By the

method of chemical vapor deposition-infiltration (CVD/CVI),

metal tantalum deposition is taking place on carbon skeleton and

a porous metal construction is formed. Due to crystallographic

processes and the tantalum’s orientation during the deposition,

this procedure leads to the creation of a surface with special

texture, similar to the cancellus bone. The mean pore’s diameter

is 547+/- 52μm.

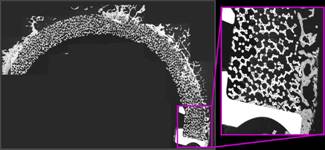

Pores are connected with smaller holes. The pore’s

two-dimensional size is 430 +/- 270

μm.

The porosity is about 75%-80% of the total material’s volume.

Pore’s size is ideal for vascular tissue ingrowth. The large

amount of empty space in this material allows deep and extensive

tissue penetration (Fig 2) and this results to stronger adhesion

and biological fixation19. This geometry also allows

the penetration of non-biological materials, as polyethylene,

that can be press - molded onto shell leading to a strong

monoblock construction. Moreover, this allows, potentially, the

deposition of osteoinductive and osteoconductive factors20

which promote the material’s bone integration. The thin coating

layer from tantalum at the initial scaffold, with thickness 10μm-100μm,

can give high mechanical properties, because this deposition has

100% density, the granule’s metal size is less than 1-5μm

and other’s material mixing is less than 0,05%. The typical mean

thickness of tantalum coating is 50

μm.

This microarchitecture possibly participates in the overall

osteogenic response, as has been proven in the past from studies

in cell cultures with materials21 of similar

microarchitecture.

Porous tantalum has also favorable elasticity and friction ratio21.

Biomaterial’s elasticity is 3GPa, very close to subchondral

bone, and this permits the normal load transferring from implant

to the surrounding cancellous bone. This is an important factor

for implant’s long-lasting survival. Tantalum’s resistance at

compression is 50-80 Mpa, almost like cancellus bone, and the

resistance at rotational deformity is 40-60Mpa. The resistance

threshold in traction is 18-20Mpa. As a result, porous tantalum

has a high degree of plasticity in compression without failure,

and can afford the usual loads of total hip arthroplasty or

while supporting the femoral head as a rod in cases of femoral

avascular necrosis. The same happens in the area of bone grafts,

where resistance at compression-traction-bending appears in ex

vivo studies to be larger than cancellous bone’s and others

metal scaffold’s resistance. This supports the hypothesis of a

more stable mechanical environment after implantation, where we

expect integration and bone penetration at scaffold. Also,

tantalum has higher friction ratio with bone, in comparison with

other porous materials. This factor increases the initial

stability after implantation. The preparation method of porous

tantalum and the mechanical properties mentioned above, allow

its formation in a variety of simple or complicated shapes,

sometimes even individual patterns, either as coating surfaces,

or as a structural bulky material. As a conclusion, in

comparison with the conventional metallic materials used in

orthopaedic surgery, porous tantalum has a significantly greater

rate of porous texture, lower rigity -similar to cancellous

bone- and higher friction ratio, which is important in the

initial stability after implantation. In comparison with bone

grafts, it has similar geometry, more predictable quality and

mechanical properties, which are constant and not downgraded

after material’s implantation.

Fig 1.

Porous tantalum’s characteristic duodenofundament structure.

In vivo experimental data

Bobyn et al22 studied biological processes at

bone-porous tantalum interface in skeletal mature dogs, after

implantation of a tantalum rod at the femoral cortical bone. The

progress in bone penetration was recorded at 4, 16, and 52

weeks, after excision of the area of implantation and expression

of the bone penetration as the rate of available pores that have

been filled with new bone. Two different sizes of pores were

studied, big (650μm)

and small (430μm)

diameter and the rates of filling at 4-16-52 weeks were: at 4

weeks 52,9% / 41,5%, at 16 weeks 69,2% / 63,1% and at 52 weeks

70,6% / 79,7% respectively. These differences are not important

in clinical practice. A material with smaller pore’s diameter is

preferable, because it is mechanically more stable due to its

thicker scaffold rods. New bone formation at porous tantalum -

implant interface followed fixed pattern: at 2 weeks it appeared

intramedullary and at the limits of the cortical drilled hole.

New bone at scaffold rods was observed in small amounts at 2

weeks, with small increase at 3 weeks. However, at 4 weeks the

new bone’s penetration at porous tantalum was a constant finding

in a big rate of surface and very often at the whole sectioning

diameter. At 16 and 52 weeks bone penetration was dense and

extensive, while the new bone in the scaffold and surrounding

cortical bone had histological findings of bone remodelling.

Haver’s system formation was present in the first case and

increased blood flow and porous texture in the second. At 4

weeks, the mean mechanical power of fixation was 18,5Mpa

(shearing resistance), which is obviously greater in comparison

with other studies of similar protocol involving other metallic

porous materials (1,2-13,1 Mpa). This difference is due to the

higher rate of porous texture, which results, for the same

volume of metallic porous scaffold and the same rate of

available empty space, in a greater amount of bone penetration

(in absolute prices). This fact theoretically leads to higher

mechanical tolerance in a shorter period of time. The same group

studied the porous tantalum’s behavior in a completely

functional, normally loaded model of total hip replacement in

dogs19. The material was used as a metallic shell in

a hemispherical acetabular component where the polyethylene was

integrated in the shell with a special procedure (compression

molding) in a depth of 1 mm. In this way the distal 2mm of the

porous tantalum’s diameter were left available for bone

penetration. The implant was removed after 26 weeks, en block

with the surrounding acetabular bone. After sectioning in

frontal level, in pieces of 2mm thickness, which were separated

in 5 consecutive zones with equal angle, radiological

examination revealed stable adhesion in the circumference (zone

A and E) where the acetabular bone had greater radiological

density. In a line with the dome of the hemispherical component

(zone C), a radiological lucent sign appeared, until 3mm, as it

was expected according to the technique of implantation (press

fit, based on the periphery of the implant). However, in most

cases there was a radiologic impression of filling of the lucent

sign with new bone. This impression was proved after

histological examination. The analysis of bone penetration in

electronic microscope was as following: at zones A, E the

greater amount of new bone formation was measured, approximately

25,1%. At these zones, who are in the periphery of the

acetabulum, the contact between component and bone was obviously

more uniform and the bone more thick. The total amount of

filling was 16,8%, and 17,3% if the zone C was excluded. At this

zone, as expected, the bone’s penetration ranged from nothing to

very little. These rates are comparable with those for other

porous materials. However taking into account the absolute bone

mass per volume of material, the porous tantalum is superior,

thanks to the greater amount of porous texture. This is

equivalent to greater mechanical resistance of the interface.

Signs of new bone formation were observed outside of the

implant’s zone and acetabular limits, rarely with histological

continuity with the new bone at zones A and E. This finding is a

strong sign of osteoinductive properties. Histologically the new

formed bone had normal structure, normal cellularity and

vascularity, without cysts or osteoclastic activity. Pores not

occupied from bone were occupied with dense fibrous tissue. This

is desirable because the lack of free pores acts as a barrier to

the synovial and wear products. We must note here, that porous

tantalum’s ability for adhesion to fibrous tissue and

regeneration of the latter has been studied experimentally by

placing it into dog’s subcutaneous tissue23. Older

studies24 showed that fibrous tissue appears

histologically a healing ability in contact to porous structures

with pore’s diameter bigger than 50μ.

In this study a satisfactory penetration of dense, vascular

fibrous tissue was observed, with similar histological and

mechanical resistance features as a normal healing fibrous

tissue. Andreykiv et al25 interpret the bone

penetration in porous tantalum as a procedure proportional to

bone healing. Under the condition of initial mechanical

stability, the initial filling with granuloma tissue is followed

by the procedure of endomembranous ossification. The meaning of

stable mechanical environment has to do with the limitation of

micro-movements under limits which are different, depending on

the interface. This critical limit has not been elucidated about

the porous tantalum and this is why the above scientists take

into account in their studies the number of 20μm,

which is very low, but offers security to accept the results.

The bone in the interface is a source of vessels and osteoblasts.

After implantation, mesenchymal cells migrate from the surface

to the porous tantalum. Mesenchymatic cells differentiate

according to the model of Prendergast et al26

depending on the stimulation from 2 different biophysical

factors, the maximum tension of shearing deformity

γ

and the relevant velocity liquid/solid

ν.

High levels of these stimulate the differentiation of

mesenchymatic cells to fibroblasts, intermediate levels to

chondral cells, while low levels to osteoblasts. The

differentiation to mixed row cells is possibly based on the

above model. So the initial mechanical stability is important

for the penetration from mesenchymatic cells and the

differentiation to bone.

Fig 2.

Deep and extensive bone penetration in an acetabular cup

implanted for 52 weks in a full loading canine model

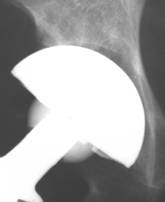

Histological data from retrieved

implant’s analysis

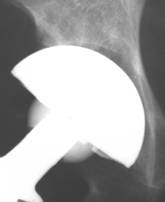

Histological studies, with electronic microscope, of an

acetabular porous tantalum implant, which was removed after

recurrent hip dislocation two years after surgery27,

revealed bone penetration and bone adhesion in the entire

surface of the implant. (Fig 3) Electronic microscopic study

depicted deep bone penetration, particularly in the periphery of

the shell, without fibrous tissue interposition in bone-tantalum

interface. Histological depiction was compatible with the

radiological depiction of complete implant’s integration.

Fig 3.

Retrieved TMT acetabular component. Excision was performed with

the use of a special cutting instrument due to stable bony

fixation.

Clinical data from the use of TMT cups

and other applications

The TMT acetabular component consists of a porous tantalum shell

with an elliptical flat shape geometry and a solid attached

polyethylene after specific preparation (compression molding).

Polyethylene’s penetration into the metallic scaffold is about

1-2mm and available depth left for bone penetration about 2-3mm.

Patients with sufficient bone substrate for peripheral support

of the acetabular component were included in a multicenter

prospective study28, where specific interest was

given in the presence, in the AP pelvis radiograph, of bone gap

and it’s progression. Acetabular-component interface was

separated in 3 contiguous zones 60ο

each, in a variant of De Lee and Charnley zones. Among 574 total

hip arthroplasties, 414 were observed for a minimum of 2 years.

20% presented in the initial radiograph with a “gap” located in

the central zone II, as expected. The width of half

of

these gaps was more than 1mm, ranging 1mm-5mm. At the last

examination (2-5 years) the gap had disappeared in 85% of the

cases, including all of the 5mm gaps, while the same happened

with 10 co-existing osteoarthritic cysts. At arthroplasties

without initial gap, the last examination revealed new lucent

line in 9%, smaller than 1mm, limited in one only zone, with

equal distribution between the three zones. In total, with

radiographic criteria, 412 of 414 arthroplasties were stable,

via bone integration, without migration. The fact that bone gap

filing is taking place with new bone formation and without

acetabular component migration, has been proven by a study of

migration of this acetabular implant with the EBRA software29.

This specific software can estimate the bone gaps with accuracy

rate of 0,1mm and after reduction to scale 1:1,15 based on the

distance between the radiology source and the pelvis, so the

measures are in agreement with the real dimensions. It also

allows the analysis of the radiographs after scanning in a high

analysis electronical scanner and the estimation of possible

implant’s migration in relation to stable parts of the pelvis,

eliminating systematic errors from possible pelvis inclination.

In this study at the equatorial of the implant, “gaps” were

found of 4mm max, at 25 from a total of 180 total hip

arthroplasties during 1998-2001. After 12-24 weeks all the gaps

were restored (Fig 4 and 5), without component migration in any

axis. In specific, implant’s migration was 0,01mm at X axis and

0,02mm at

Ψ

axis, which practically means absence of migration. These hips

were subsequently followed30 for a

time ranged from 8 to 10 years. For the purpose of this study,

151 hips were available for final evaluation. The average

pre-operative total Harris Hip Score was 44.0 ± 13.8 (4 to

86.75), increased at one-year to 95.2 ± 4.8 (81 to 100) (p <

0.05) and remained constant through the latest follow-up at

97.0 ± 6.2, (58.85 to 100) (p < 0.05). The average Oxford Hip

Score improved from a preoperative score of 43.3 ±6.5 to 15.2

±2.3 at one-year postoperatively and 13.9 ±2.3 at the latest

follow up. There was no radiographic evidence of gross

polyethylene wear, progressive radiolucencies, osteolytic

lesions, acetabular fracture or component subsidence. There were

7 (4.5%) postoperative complications all unrelated to the

acetabular component. This study reveals both clinical and

radiographic evidence of well fixed and stable acetabular

components through 8-10 years, thus confirming the initial

hypothesis of increased early stability, safe osteoindegration

and more “physiologic” load transfer of the tantalum acetabular

component. During the last decade porous tantalum has been used

in several orthopaedic applications. Its use in hip arthroplasty

has been extended from primary to revision cases.

Cementless acetabular revision with the tantalum acetabular

shell demonstrated excellent clinical and radiographic results,

even with severe (Paprosky 3A and 3B) acetabular bone defects31,32.

In the area of knee arthroplasty,

porous

tantalum metaphyseal cones33 effectively provide

structural support for the tibial implants and is a good

treatment method for large tibial bone defects during revision

knee replacement. Porous tantalum cone has also been used34

as an “internal plate” for reconstruction of a combined

segmental/cavitary defect of the proximal tibia in difficult

cases sush as Charcot Arthropathy.

Support of femoral head35,36 in avascular necrosis-

Ficat stages I and II- with porous tantalum rods has shown good

results, comparable with those using vascular fibular autograft.

Other applications include salvage patella replacement37,38,

oncological

implants39 for bone integration and soft tissues

adhesion, carpal-cubitocarpal joint fusion40,

arthrodesis in cervical and lumbar spine41,42,

subchondral replacement scaffolds43 in chondral

lesions repair.

Recent experimental

studies in a model of hip arthroplasty in dogs44 have

shown that combining a tantalum’s shell with an intravenous dose

0,1 mg/kg of biphosphonate zoledronic acid immediately after

surgery, led to a 85% greater bone formation into the porous

material, 6 weeks after implantation. This finding means that

porous tantalum in combination with biphosphonates can increase

the biological fixation into the bone’s interface. This

combination, as proved by recent experimental studies45,

can be performed and with local use of biphosphonate after

physical and chemical connection with hydroxyapatite coated

porous tantalum implant: intramedullary implantation in ulna

bone at a dog showed statistically important greater area of

surface been bone integrated and in total, greater volume of new

bone formation in contact and around the implant.

Fig 4.

Polar gap at the initial AP radiograph. The gap was filled with

new bone formation at 24 weeks. Despite the fact that the

periphery of the implant was left uncovered, the arthroplasty

functions well, without signs of loosening at the latest follow

up

Fig 5.

New bone formation onto uncovered shell. This is a sign of

implant’s osteoinductive properties.

Conclusions:

Porous tantalum is a relatively new biomaterial with unique

mechanical properties. It has a great porosity, up to 80% of its

volume, that favors bone penetration and osteoindegration. Its

elasticity is close to subchondral bone, offering more normal

patterns of load transmission, while at the same time its

adherent nature offers initial stability after implantation;

this ensures a mechanically stable environment which is

important for favorable long term results. The capability of

different shapes and patterns in manufacturing allows the

consideration of porous tantalum in a variety of orthopaedic

surgical applications. For any implant, where we require good

long-lasting functionality, the proof in practice with

continuous observation is essential. This is established by

long-lasting clinical prospective studies, and

laboratory-histological examination of well-functioning implants

which are removed for some reason. Experimental data, however,

and the first to mid-term clinical results, indicate that the

unique physical and chemical properties of porous tantalum

provide new opportunities in construction and application of

orthopaedic implants.

Reference :

-

Cook SD, Barrack RL, Thomas KA, Haddad RJ. Quantitative

analysis of tissue growth into human porous total hip

components. J Arthroplasty 1988;3:249-62.

-

Engh CA, Zettl-Schaffer KF, Kukita Y, et al.

Histological and radiographic assessment of well functioning

porous-coated acetabular components: a human post-mortem

retrieval study. J Bone Joint Surg [Am] 1993;75-A:814-24.

-

Pidhorz LE, Urban RM, Jacobs JJ, Sumner DR, Galante JO. A

quantitative study of bone and soft tissues in cementless

porous-coated acetabular components retrieved at autopsy. J

Arthroplasty 1993;8: 213-25.

-

Black J. Biological performance of tantalum. Clin Mater.

1994;16:167-173

-

Burke GL. The corrosion of metals in tissues and an

introduction to tantalum. Canada Med Ass. J. 1940;43:125-128

-

ASTM. Standard specification for unalloyed tantalum for

surgical implant applications (ASTM F 560-98). In: Annual Book

of ASTM Standards, ASTM, 1998;13.01:63-65

-

Johnson PF, Bernstein JJ, Hunter G, Dawson WW, Hench LL.

An in vitro and in vivo analysis of anodized tantalum

capacitive electrodes: corrosion response, physiology and

histology. J Biomed Mater Res 1977;11:637-56.

-

Pudenz RH. The repair of cranial defects with tantalum: an

experimental study. J Amer Med Assoc 1943;121:478-81.

-

Brown MA, Carden JA, Coleman RE, McKinney R Jr, Spicer LD.

Magnetic field effects on surgical ligation clips. Magn Reson

Imaging 1987;5:443-53.

-

Plenk

H Jr, Pfluger G, Schider S, Bohler N, Grundschober F. The

current status of uncemented tantalum and niobium femoral

endoprostheses. In: Morscher E, ed. The cementless fixation of

hip endoprostheses. Berlin: Springer-Verlag, 1984:174-7.

-

Spurling RG. The use of tantalum wire and foil in the repair

of peripheral nerves. Surg Clin North Am 1943;23:1491-504.

-

Aronson AS, Jonsson N, Alberius P. Tantalum markers in

radiography: an assessment of tissue reactions. Skeletal

Radiol 1985;14: 207-11.

-

Grundschober F, Kellner G, Eschberger J, Plenk H Jr.

Long-term osseous anchorage of endosseous dental implants made

of tantalum and titanium. In: Winter GB, Gibbons DF, Plenk H

Jr, eds. Biomaterials 1980. Chichester: John Wiley & Sons,

1982:365-70.

-

Kokubo T.

, Kim HM et al Metallic materials stimulating bone formation

Med J Malaysia. 2004 May;59 Suppl B:91-2.

-

Findlay DM,

Welldon K,

Atkins GJ,

Howie DW,

Zannettino AC,

Bobyn D

The proliferation and phenotypic expression of human

osteoblasts on tantalum metal. Biomaterials. 2004

May;25(12):2215-27

-

Welldon KJ, Atkins GJ,Howie DW, Findlay DM.Primary human

osteoblasts grow into porous tantalum and maintain an

osteoblastic phenotype. J Biomed Mater Res A. 2008 Mar

1;84(3):691-701

-

Stackpool GJ, Kay AB, Morton P, et al. Bone ingrowth

characteristics of porous tantalum: a new material for

orthopaedic implants. Trans Combined ORS, 1995:45

-

Cohen R. A porous tantalum trabecular metal: basic science –

review paper. The Am J of Orth 2002 Apr;31(4):216-7.

-

Bobyn JD, Toh K-K, Hacking SA, et al. the tissue response to

porous tantalum acetabular cups. A canine model. J Arthr.

1999;14:347-354

-

Kieswetter K, Schwartz Z, Hummert TW, et al.

Surface roughness modulates the local production of growth

factors and cytokines by osteoblast-like MG-63 cells.

J Biomed Mater Res 1996;32:55-63.

-

Krygier JJ, Bobyn JD, Poggie RA, Cohen RC. Mechanical

characterisation of a new porous tantalum biomaterial for

orthopaedic reconstruction.

SIROT, Sydney, 1999.

-

Bobyn JD, G. J. Stackpool, S. A. Hacking, M. Tanzer, J. J.

Krygier . Characteristics of bone ingrowth and interface

mechanics of a new porous tantalum biomaterial JBone Joint

Surg (Br) 1999; 81-B: 907-914.

-

Hacking SA,

Bobyn JD,

Toh K,

Tanzer M,

Krygier JJ.

Fibrous tissue ingrowth and attachment to porous tantalum. J

Biomed Mater Res. 2000 Dec 15;52(4):631-8.

-

Gottsauner – Wolf F, Egger EL, Chao EY, et al. Tendons

attached to prostheses by tendon – bone block fixation. An

experimental study in dogs. J Orth Res 1994;12:814-821

-

Andreykiv A, Prendergast PJ, Kuelen F, Swieszofsky W, Rozing

P. Bone ingrowth simulation for a concept glenoid component

design. J Biomech. 38(2005) 1023-1033

-

Prendergast PJ, Huiskes R, Soballe K. Biophysical stimuli on

cells during tissue differentiation at implant interfaces. J

Biomech. 1997 30(6), 539-548

-

Bobyn JD (Jo Miller Laboratory, Montreal, Canada), Case:

Michelinakis E

-

Gruen TA, Poggie RA, et al. Radiographic Evaluation of a

Monoblock Acetabular Component.

A Multicenter Study with 2- to 5-Year Results. J Arthr 2005

20(3): 369-378

-

Kostakos AT,

Macheras GA,

Frangakis CE,

Stafilas KS,

Baltas

D,

Xenakis

TA, Migration of the Trabecular Metal Monoblock

Acetabular Cup System A 2-year follow-up using the

Ein-Bild-Röntgen-Analyse method.

J

Arthroplasty. Acc. 2008 Dec, ahead of print

-

Macheras G, Kateros K, Kostakos A, Koutsostathis S, Danomaras

D, Papagelopoulos PJ, Eight- to Ten-Year Clinical and

Radiographic Outcome of a Porous Tantalum Monoblock Acetabular

Component. J Arthroplasty.

2009 Aug;24(5):705-9

-

Kim WY, Greidanus NV, Duncan CP, Masri BA, Garbuz DS. Porous

tantalum uncemented acetabular shells in revision total hip

replacement: two to four year clinical and radiographic

results. Hip Int. 2008 Jan-Mar: 18(1):17-22

-

Weeden

SH,

Schmidt

RH. The use of tantalum porous metal implants for

Paprosky 3A and 3B defects. J Arthroplasty.

2007 Sep;22(6 Suppl 2):151-5.

-

Meneghini RM,

Lewallen DG,

Hanssen

AD. Use of porous tantalum metaphyseal cones for

severe tibial bone loss during revision total knee

replacement. J Bone Joint Surg Am. 2008

Jan;90(1):78-84.

-

Troyer J. Levine BR.Proximal tibia reconstruction with a

porous tantalum cone in a patient with Charcot arthropathy.

Οrthopedics 2009 May: 32(5):358

-

Veillette CJ,

Mehdian

H,

Schemitsch EH,

McKee

MD. Survivorship analysis and radiographic outcome

following tantalum rod insertion for osteonecrosis of the

femoral head. J Bone Joint Surg Am. 2006

Nov;88 Suppl 3:48-55.

-

Tsao AK,

Roberson JR,

Christie MJ,

Dore DD,

Heck DA,

Robertson DD,

Poggie RA.

Biomechanical and clinical evaluations of a porous tantalum

implant for the treatment of early-stage osteonecrosis. J Bone

Joint Surg Am. 2005;87 Suppl 2:22-7.

-

Nasser S,

Poggie RA

Revision and salvage patellar arthroplasty using a porous

tantalum implantJ Arthroplasty. 2004 Aug;19(5):562-72.

-

Ries MD, Cabalo A., Bozic KJ, Anderson M.Porous tantalum

patellar augmentation: the importance of residual bone stock.

Clin Orthop Relat Res 2006 Nov :452:166-70

-

Chalkin B,

Minter J.

Limb salvage and abductor reattachment using a custom

prosthesis with porous tantalum components. J Arthroplasty.

2005 Jan;20(1):127-30.

-

Adams JE,

Zobitz ME,

Reach JS Jr,

An KN,

Lewallen DG,

Steinmann SP

Canine carpal joint fusion: a model for four-corner

arthrodesis using a porous tantalum implant. J Hand Surg [Am].

2005 Nov;30(6):1128-35.

-

Zou X,

Li H,

Teng X,

Xue Q,

Egund N,

Lind M,

Bunger C

Pedicle screw fixation enhances anterior lumbar interbody

fusion with porous tantalum cages: an experimental study in

pigs. Spine. 2005 Jul 15;30(14):E392-9.

-

Wigfield C,

Robertson J,

Gill S,

Nelson R.Clinical

experience with porous tantalum cervical interbody implants in

a prospective randomized controlled trial. Br J Neurosurg.

2003 Oct;17(5):418-25.

-

Mardones RM,

Reinholz GG,

Fitzsimmons JS,

Zobitz ME,

An KN,

Lewallen DG,

Yaszemski MJ,

O'Driscoll SW.

Development of a biologic prosthetic composite for cartilage

repair. Tissue Eng. 2005 Sep-Oct;11(9-10):1368-78.

-

Bobyn JD,

Hacking SA,

Krygier JJ,

Harvey EJ,

Little DG,

Tanzer M.

Zoledronic acid causes enhancement of bone growth into porous

implants 2005Mar;87(3):416-20.

-

Tanzer M,

Karabasz D,

Krygier JJ,

Cohen R,

Bobyn JD.The

Otto Aufranc Award: bone augmentation around and within porous

implants by local bisphosphonate elution. Clin Orthop Relat

Res. 2005 Dec;441:30-9.

|