|

Abstract:

The

risk of disease transmission from human musculoskeletal

allograft tissue distributed by tissue banks is a subject of

ongoing concern. Efforts

to minimize disease transmission have generally included donor

screening, bioburden assessment, aseptic handling, chemical

washes, antibiotics, and gamma irradiation.

Without adequate sterilization, however, viral and

bacterial contamination of allograft tissue remains a

significant problem.

Achieving terminal sterilization to a sterility assurance

level of 10-6 (SAL6; the standard for medical

devices) frequently compromises biomechanical properties in the

allograft. Here

we report that SAL6 sterilization of human allografts can be

achieved using supercritical CO2 with a peracetic

acid-based additive.

The biomechanical properties of allografts sterilized

with supercritical CO2 are superior to those

sterilized by traditional gamma irradiation. These findings

suggest that supercritical CO2 sterilization of human

allograft tissue will increase the safety of allograft tissues

while maintaining biomechanical properties.

J.Orthopaedics 2009;6(2)e9

Keywords:

sterilization;

supercritical carbon dioxide; allograft tissue; bone

Introduction:

The importance of

allograft tissue in the treatment of musculoskeletal disorders

has grown dramatically since 1990. Such disorders are the most

frequently identified impairments of physical health in the

United States (US). It has been estimated that over 36 million

Americans suffer from musculoskeletal conditions that limit

their ability to function, with costs to society exceeding one

billion dollars annually (1).

Allograft tissue is

widely used by transplant surgeons for orthopedic (joint

replacement), trauma, and cancer (surgical reconstruction)

procedures (2), (3), (4), (5). In the US, tissue bank

distribution of such allografts has increased from 350,000

specimens in 1990 to over 1.6 million in 2005 (1), (6). The

need for safe and effective allografts continues to grow as

allogenic transplantation has become the clinical therapeutic

strategy of choice to combat musculoskeletal disorders.

US tissue banks that

supply allografts from cadavers have traditionally operated with

relatively little regulatory oversight. In the past, bacterial

and viral infections derived from transplanted musculoskeletal

tissues have been rare events. However, the potential for

disease transmission remains a major concern for clinicians and

patients (7). Now, with demand growing for allografts, the US

Food and Drug Administration (FDA) has introduced requirements

for the manufacture of allograft tissue [21 CFR parts 1270 and

1271].

Despite more stringent

regulations, tissue banks continue to utilize aseptic processing

strategies, which may increase the potential risk to patients

from non-sterile allografts. Current allograft processing

techniques often involve several disinfectant steps following

aseptic donor harvest, including soaking in disinfectants and

exposure to a sterilization step (8), (4), (9). Allograft

tissue samples processed by such methods have generally failed

to achieve sterility assurance levels of 10-6 (SAL6) as required

for the sterilization of medical devices (3), (4), (8), (10).

Moreover, preserving the osteogenic and biomechanical properties

of structurally complex allograft tissue has proven to be

challenging.

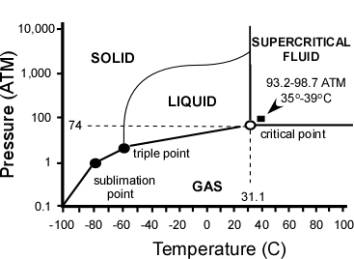

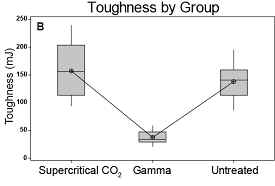

Figure

1 – Phase Diagram of CO2.

Carbon Dioxide has four distinct phases; the standard solid,

liquid and gas as well as the unique supercritical phase.

We have developed a

method for sterilizing musculoskeletal allografts using

supercritical carbon dioxide (SCCO2) [US patent 7,108,832] that

involves the use of low temperature, low pressure and

proprietary nontoxic sterilization additive. Carbon dioxide

has a unique critical point, defined by pressure (Pc=1,099 psi)

and temperature (Tc=31.1˚C) at which the liquid and vapor phases

become indistinguishable (Figure 1). With its low surface

tension, liquid-like density and gas-like diffusivity, SCCO2 is

also ideal for temperature sensitive materials.

Previous research has

shown that proteins and other macromolecules are unreactive

towards SCCO2 (11). SCCO2 successfully inactivates viruses and

produces minimal inflammatory reaction and satisfactory

integration when used in conjunction with hydrogen peroxide on

sheep bone allografts (12), (13). Here we describe a novel

method to achieve SAL6 using musculoskeletal allograft tissue

that is terminally sterilized in double Tyvek® packaging.

Moreover, we demonstrate that the sterilization process does not

compromise the biomechanical properties of the bone allograft.

The method achieves terminal sterilization while avoiding the

damage caused by gamma or other processing methods. Our

experiments further indicate that sterilization by SCCO2

represents a viable solution to the pressing need to terminally

sterilize musculoskeletal allograft tissue.

Materials

and Methods:

Allograft tissue samples

Bone-tendon-bone (BTB)

and large tendon (Achilles and Tibialis; designated as research

tissue) were provided by Community Tissue Services (CTS)

(Dayton, OH). Biomechanical studies utilized nine sets of

trisected BTB samples from nine different donors (three BTBs

harvested per donor).

Cortical rings (femur

and tibia) 15mm in height were also provided by CTS. Femoral

cortical bone struts measuring 4mm (W) x 4mm (H) x 30mm (L) were

used in biomechanical studies. Twelve groups of three struts

per group were procured from a single donor at the same femoral

location and with the same orientation.

Allograft tissue

samples used in sterilization protocols were processed either by

Allowash™ or rinsed only with normal saline solution (0.9g NaCl).

Tissue designated as “Allowashed” was processed using Allowash™

(LifeNet, VA) at CTS prior to SCCO2 treatment at NovaSterilis.

Tissue designated as “saline rinsed” was rinsed extensively with

sterile saline solution at NovaSterilis prior to SCCO2

treatment.

Sterilization Protocols/ Microbiological Assays

Gamma irradiation for

biomechanical studies was performed by Sterigenics (Westerville,

OH) at ambient temperature using a dose of 15-25 kGy.

SCCO2 sterilization was

performed in-house using the 20 L Nova2200™ instrument.

Sterilization runs were conducted using NovaKill™ additive (peracetic

acid based additive; 16 mL per run). Additive was pipetted onto

a 1 ½” x 7 ⅞” cellulose pad, which was then secured in the

chamber’s lower 1” stainless steel basket using a holder.

Allograft samples terminally sealed in double Tyvek® pouches

were arranged in stainless steel baskets (7” and 5”), which were

stacked in the chamber. The Nova2200™ containing samples and

additive was then charged with CO2 from ambient conditions in

6-9 minutes to a pressure of 1436 ± 70 psi and a temperature of

35 ± 3˚C with constant stirring (680 ± 20 rpm). System

parameters and run times were maintained as specified, following

which the vessel was depressurized over 15-25 minutes.

Sterilization run times

for tendon or bone allografts inoculated with B. atrophaeus

spores were determined conservatively by fraction negative

analysis, following ISOs 11138-1, 14937, and 11737-1.

Allograft samples were inoculated with Bacillus atrophaeus spore

suspensions (>106 CFUs/10μL in aqueous solution) (SGM Biotech,

MT) for fraction negative testing. Inocula (10μL) were allowed

to permeate the grafts at room temperature for 15 minutes. Each

allograft sample was transferred to the appropriately sized

Tyvek® gas-permeable pouch, which was sealed before being

inserted into a second terminally sealed Tyvek® pouch prior to

sterilization treatment.

Allograft samples were

then exposed to SCCO2 for various time intervals. To assay for

microbiological growth following treatment, allograft tissue

samples were aseptically removed from packaging and cultured in

bottles containing tryptic soy casein broth (Bacto) at 35˚C.

Each sample culture was observed daily for turbidity over a

period of 7 days and scored for no growth (0) or growth (+).

Samples scoring negative for growth after 7 days were spiked

with 10-100 CFUs B. atrophaeus to test for bacteriostasis. If

growth was observed in the spiked media, the sterility test was

affirmed and the tissue judged sterile.

The total time or full

cycle of the process corresponds to twice the time calculated to

result in the 6 log reduction as demonstrated by the time to

achieve total kill in microbiological methods. This method is

in compliance with the “overkill” methodology outlined in ISO

11737-1 and as required for SAL6.

Biomechanical Testing

Biomechanical testing

was performed by IMR Test Labs (Lansing, NY). Creep testing was

performed on an Instron Dynamite fatigue tester (Model 8841).

Each BTB allograft was clamped on bone sections using standard

wedge grips. The samples were manually cycled three times from

50N to 80N for preconditioning and loaded to 8N with the width

of thickness of the tendon in the midpoint measured using

digital calipers. To determine creep measurements, the gap

between the substantial bone segments was also measured.

Samples were then

subjected to tension cycles (1 sec) from 50N to 250N in a

sinusoidal waveform, followed by a hold (15 sec) at 50N for a

total of 100 cycles. The final length between the bone sections

was measured at 8N and the creep of the samples calculated as in

Equation 1.

Creep (%) = (final

length – original length)/original length x 100

Equation 1

The samples were loaded

to failure using an Instron Tensile Tester (Model 5584). The

tibia section of the BTB was mounted inside plastic cylinders

using epoxy resin. A 3/8” diameter dowel was inserted between

the bone end and the tendon to prevent tearing. The midpoint of

each tendon was trimmed to 5 mm. The patellar bone section was

placed in standard wedge grips. The reduced section width was

measured and the samples were then pulled at a crosshead speed

of 0.5 inches per minute until a significant load drop was

recorded. From the load deflection data, the peak stress,

elongation at break (based on 1 mm gauge length) and modulus

were calculated.

For tendon

biomechanics, 9 sets of trisected BTBs consisting of 3 BTBs

harvested per donor (27 total samples) were divided into three

groups. SCCO2 sterilization was carried out for 4 hours

(overkill from half cycle 90 min; SAL6). All BTBs were loaded

onto an Instron tensile testing machine and forced to failure at

a rate of 1 inch elongation/minute. Tensile strength was

calculated as the maximal load divided by the cross sectional

area.

For bone biomechanics,

36 bone struts (4mm x 4mm x 30mm) consisting of 3 cortical

struts harvested per donor from the same location and

orientation were divided into 3 groups with 12 struts each (one

per donor). These groups consisted of untreated, traditional

gamma irradiated, and SCCO2 sterilized. SCCO2 sterilization was

carried out for 70 minutes (overkill, strut half cycle 20

minutes). Subsequent to the respective treatments all bone

struts were measured for density, 3 point bending, ash fraction,

and collagen cross-linking.

Bone density

measurements were performed according to ASTM D 792-00. The

struts were subsequently incubated at room temperature in

phosphate-buffered saline (PBS) for 48 hours and kept moist

during the testing. Three point bending was carried out in

accordance with ASTM D 790-03 using an Instron Model 5584

Universal Tester controlled by Instron Merlin software. The

specimens were supported using a 20mm span (L) with a 4.8mm

loading diameter. The load was applied to the center of the

specimen (L/2) at a rate of 1 mm/min. Flexural modulus was

calculated from the slope of the loading curve. Flexural

strength was calculated following ASTM D 790-03 by integrating

the area under the stress-strain curve.

After the bending tests

were completed, the two halves of the failed specimens were

examined to determine mineral content and collagen

cross-linking, respectively. Ash fraction was measured by

ashing the specimens (ash mass/dry mass) (ASTM D 4630-01 with

slight modification). Bone samples were dehydrated by

incubating at 100˚C for 48 hours, weighed, and then incubating

at 800˚C for 24 hours. The remaining ash was weighed and

divided by the dry weight to determine the ash fraction.

Collagen cross-linking

Collagen cross-linking

analysis was performed by Articular Engineering, LLC

(Northbrook, IL). Samples were first powdered using liquid

nitrogen, demineralized using ethylenediaminetetraacetic acid (EDTA),

and papain digested. For each digest, two aliquots (2 mL each)

were hydrolyzed using hydrochloric acid (HCl). Hydroxy-lysyl

pyridinoline and lysyl pyridinoline were separated using

cellulose column chromatography and lyophilized samples were

resuspended in 400 μL of 1% heptafluorobutyric acid in double

distilled H2O (ddH2O). Aliquots (100 μL) were assayed using

high performance liquid chromatography (HPLC).

Calculations

Statistically

significant differences between experimental and control groups

were determined using analysis of variance (ANOVA) and paired

T-testing using Prism graphpad software (Graphpad Software, CA).

Results :

The term “Sterility

Assurance Level” (SAL), is routinely used in relationship to

sterilization and is the probability of one microbial survivor

is one in one million. B. atrophaeus endospores have been

previously shown to be the most resistant microorganism to

sterilize using our SCCO2 technology (11). Inactivation

kinetics of B. atrophaeus was examined by construction of a

survivor curve by plotting the percent survival of B. atrophaeus

as a function of time. Ideally, the survivor curve is linear

over the full range of inactivation. Using the fraction

negative method we show linear inactivation of greater than 106

CFUs B. atrophaeus spores on saline rinsed tendon using SCCO2

sterilization (Figure 2). Similar data was obtained for bone,

but is not shown. Samples of Allowashed™ tendon exposed to SCCO2

for 90 minutes cultured negative for B. atrophaeus growth, while

also passing the bacteriostasis testing. Similar sterilization

of saline-rinsed tissue required 120 minutes. Both times of

inactivation are representative of half cycles. SAL6, full

cycle sterilization times were 180 minutes and 240 minutes,

respectively.

Figure

2. Survival curve for inactivation of Bacillus

atrophaeus endospores inoculated saline rinsed tendon or

allowashed preprocessed tendon. Survival

curve for inactivation of Bacillus

atrophaeus endospores as a function of time.

Saline rinsed tendon (square) or allowashed tendon (diamond) was

inoculated with greater than 106 CFUs and subjected to

sterilization using SCCO2 and NovaKill additive at different

times. The results were calculated as positive

growth/total growth as a function of time.

Biomechanical

Figure

3 depicts differences in the biomechanical properties of

differently processed BTBs.

In samples exposed to gamma radiation, the data reveal

variation in elongation and creep for several donors.

Since elongation is a factor in creep, these observations

were unsurprising.

Although some individual donor differences in the

treatment groups were apparent, ANOVA statistical analysis

reveals no significant difference in BTB biomechanics between

the groups (Table 1).

|

|

Group

|

Mean

|

SE

|

|

|

Gamma

|

3.8

|

1.096

|

|

Creep

(%)

|

Supercritical

CO2

|

2.36

|

0.33

|

|

p

= 0.569

|

Untreated

Control

|

1.86

|

0.23

|

|

|

Gamma

|

3.235

|

1.07

|

|

Elongation

(%)

|

Supercritical

CO2

|

2.528

|

0.33

|

|

p

= 0.5306

|

Untreated

Control

|

1.884

|

0.26

|

|

|

Gamma

|

4.208

|

0.496

|

|

Strain

(%)

|

Supercritical

CO2

|

3.506

|

0.3724

|

|

p

= 0.5216

|

Untreated

Control

|

4.692

|

0.3445

|

|

|

Gamma

|

672.8

|

81.47

|

|

Load

(N)

|

Supercritical

CO2

|

683.1

|

72.39

|

|

p

= 0.154

|

Untreated

Control

|

812.2

|

86.46

|

|

|

Gamma

|

34.91

|

4.175

|

|

Tensile

Stress (MPa)

|

Supercritical

CO2

|

39.44

|

2.897

|

|

p

= 0.154

|

Untreated

Control

|

46.37

|

5.508

|

|

|

Gamma

|

3.728

|

0.33

|

|

Modulus

(MPa)

|

Supercritical

CO2

|

3.919

|

0.39

|

|

p

= 0.5690

|

Untreated

Control

|

4.3

|

0.33

|

|

|

Gamma

|

0.3

|

0.09

|

|

Fatigue

(%)

|

Supercritical

CO2

|

0.53

|

0.05

|

|

p

= 0.6543

|

Untreated

Control

|

0.49

|

0.09

|

Table 1. Results of

ANOVA calculations, Mean, and standard error for untreated

control, Gamma irradiated and supercritical CO2 treated BTBs.

Newton (N); Mega Pascal (MPa); Percent (%).

Figure

3. Graphs comparing effects of sterilization methods of

biomechanical properties of BTBs for all donors

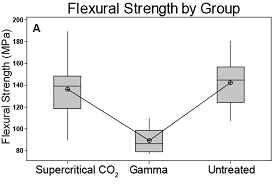

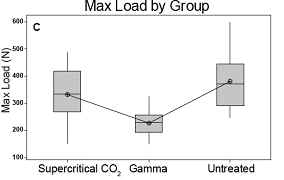

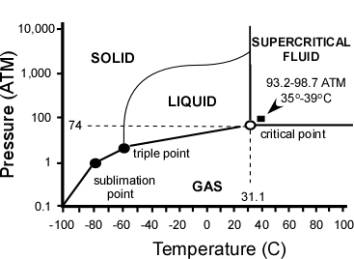

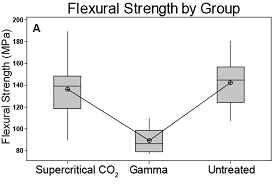

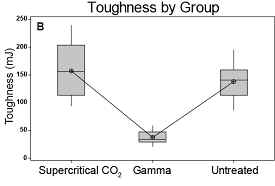

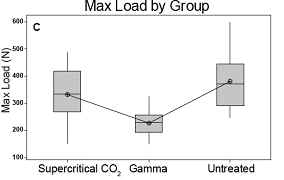

Of the biomechanical parameters monitored in bone testing, no

statistically significant differences in density, ash fraction,

and Young’s modulus were observed in the three groups (Table

2). Three-point

bending revealed that gamma sterilization negatively impacted

the biomechanical properties with respect to flexural strength,

maximum load, and overall toughness (Table 2 and Figure 4).

Figure

4. Box plots of those measures showing significant differences

between groups. A. Flexural strength, B. Toughness, and C. Max

load all are unchanged by supercritical CO2 sterilization but

compromised by gamma treatment.

|

|

Group

|

Number

|

Mean

|

StDev

|

|

Density

(g/cc)

|

Supercritical

CO2

|

12

|

1.94

|

0.05

|

|

Untreated

|

12

|

1.94

|

0.06

|

|

Gamma

|

11*

|

1.96

|

0.03

|

|

Ash

Fraction

(ash/dry)

|

Supercritical

CO2

|

12

|

0.646

|

0.011

|

|

Untreated

|

12

|

0.650

|

0.010

|

|

Gamma

|

12

|

0.649

|

0.010

|

|

Flexural

Strength

(MPa)

|

Supercritical

CO2

|

12

|

136.1

|

27.39

|

|

Untreated

|

12

|

142.05

|

20.09

|

|

Gamma

|

12

|

89.38

|

11.52

|

|

Toughness

(mJ)

|

Supercritical

CO2

|

9**

|

156.7

|

53.5

|

|

Untreated

|

9**

|

138.2

|

33.7

|

|

Gamma

|

9**

|

36.5

|

12.7

|

|

Max

Load

(N)

|

Supercritical

CO2

|

12

|

332.0

|

99.5

|

|

Untreated

|

12

|

379.9

|

100.0

|

|

Gamma

|

12

|

226.0

|

46.5

|

|

Young’s

Modulus

(MPa)

|

Supercritical

CO2

|

12

|

5320

|

1798

|

|

Untreated

|

12

|

5713

|

1231

|

|

Gamma

|

12

|

5866

|

1458

|

|

Hydroxylysyl

pyridinoline

(µmol/g)

|

Supercritical

CO2

|

12

|

8.7

|

3.1

|

|

Untreated

|

12

|

8.3

|

2.2

|

|

Gamma

|

12

|

9.3

|

2.8

|

|

Lysylpyridinoline

(µmol/g)

|

Supercritical

CO2

|

12

|

3.5

|

1.5

|

|

Untreated

|

12

|

3.3

|

1.1

|

|

Gamma

|

12

|

3.7

|

1.5

|

Table

2. Results of ANOVA calculations for Untreated, Gamma

irradiated, and supercritical CO2 treatment groups with respect

to the indicated measures. *one sample was removed due to

experimental error, ** Data from 3 independent samples per group

were excluded because clean breaks were not observed during

testing resulting in artificially inflated toughness.

Paired

T-testing confirmed no significant differences between control

(untreated) and SCCO2 sterilized cortical bone (Table 3).

By contrast, statistically significant differences were

noted between control and gamma irradiated bone (Table 2).

|

|

Flexural

Strength

(MPa)

|

Toughness

(mJ)

|

Max

Load

(N)

|

|

Untreated

|

142.1

|

138.3

|

379.9

|

|

Supercritical

CO2

|

136.1

|

145.0

|

332.0

|

|

Difference

|

6.0

p = 0.505

|

-6.7

p

= 0.58

|

47.9

p

= 0.136

|

|

Untreated

|

142.1

|

138.3

|

379.9

|

|

Supercritical

CO2

|

89.4

|

36.9

|

226.0

|

|

Difference

|

52.7

p

= 0.00

|

101.4

p

= 0.00

|

153.9

p

= 0.00

|

|

Untreated

|

136.1

|

145.0

|

332.0

|

|

Supercritical

CO2

|

89.4

|

36.9

|

226.0

|

|

Difference

|

46.7

p

= 0.00

|

108.1

p

= 0.00

|

106.0

p

= 0.00

|

Table

3 . Results of paired T-testing

for those measures with significant differences between groups.

Collagen

Cross-Linking

Analysis

of collagen cross-linking through measurement of

hydroxylysylpyridinoline and lysylpyridinoline revealed no

significant differences between control and test groups (Table

2). In

addition, no significant correlations were detected between any

of the biomechanical measures and the level of collagen

cross-links.

BTBs

Photographs

of sterilized BTBs (Figure 5) indicated that SCCO2

treatment produced significantly brighter and cleaner tendon

samples than either untreated or gamma irradiated samples.

Pre and post-sterilization weighing revealed that BTB

allografts lost approximately 14% of their mass.

That loss was attributed to extraction of lipids and

excess fluids during the sterilization process.

In fact, extracted lipid could be detected in the oily

residue present in the package after sterilization.

Figure

5. Photographs of bisected BTBs from a single donor with

respective sterilization treatments.

Discussion :

Modest, but

significant, differences were noted in the SCCO2 sterilization

of Allowashed and saline-rinsed tendon. In each case, samples

were inoculated with 106 CFUs of B. atrophaeus spores, adding to

whatever natural (presumably smaller) bioburden was already

present in the tissue samples prior to washing. A likely

explanation of these modest differences is that Allowashed

samples had an already diminished bioburden prior to

inoculation, as compared to saline-washed samples. However, the

more important conclusion is that no preprocessing is required

to achieve sterilization. Regardless of their preprocessing

history, tendon samples exposed to SCCO2 in the presence of

NovakillTM afforded sterile tissue, free of cellular or sporular

bacterial contamination.

Results from this study

also established that SCCO2 sterilization preserved the

biomechanical properties of the cortical bone. No significant

difference in all measures between SCCO2 sterilized and

untreated (Table 2, Table 3 and Figure 4) were apparent.

Preservation of these properties is important due to the fact

that grafts are largely used in load bearing orthopedic

applications. SCCO2 sterilization is effective at achieving

medical device levels of sterilization while maintaining

essential biomechanical properties.

Interestingly, while

some loss of lipid content was noted during tendon

sterilization, lipid extraction from the graft has been shown in

other studies with bone to increase graft incorporation

following transplant (14). Delipidation enhances accessibility

to microporous structures in the bone and enhances

osteoconduction following transplant (15), (16), (17). These

data demonstrated that besides achieving sterilization (SAL6),

SCCO2 treatment also preserved the biomechanical properties of

tendon.

Results reported here

show that effective (SAL6) terminal sterilization of bone and

tendon allograft tissue can be achieved while preserving

essential allograft properties and maintaining essential

biomechanical properties. Moreover, SCCO2 sterilized bone is

254% tougher, can withstand 68% greater load, and has 66% more

flexural strength than that of gamma irradiated samples.

SCCO2 sterilized

cortical bone is similar to untreated controls with respect to

pre-yield (elastic) and post yield (plastic) properties. This

observation is consistent with the preservation both of mineral

content, which is important for elastic properties, and

collagen, which is thought to preserve bone plasticity. No

significant differences in collagen cross-linking levels

relative to controls were noted in any of the test groups.

Moreover, the observation that gamma irradiated samples maintain

inherent Young’s modulus strength (an elastic property), but

exhibit reduced plasticity (i.e. toughness, flexural strength)

confirms earlier reports in the literature (5), (8).

A remaining concern

with respect to SCCO2 sterilization of bone allografts is the

osteoinduction and osteoconduction properties after

sterilization. The effect of sterilization on these processes

are not within the scope of the current study but will be

investigated in future studies. However, protein profiles and

content of Salmonella typhimurium inactivated using SCCO2

technology were unaffected when compared to protein profiles of

non-sterilized (control) cells (11). This coupled with our

current observations strongly suggests the gentle nature of this

process will preserve the essential properties of bone

allografts.

Tendon transplants

restore movement and flexion to patients suffering from loss of

function. This study demonstrates that SCCO2 sterilization can

be effective in achieving SAL6 (medical device level)

sterilization while maintaining the quality of the tendon

tissue. A remaining concern with respect to supercritical CO2

sterilization is the vascularization and cellular properties of

the tendon following transplant. Examination of cellular

structure by scanning electron microscopy (SEM) and transmission

electron microscopy (TEM) revealed no significant change in

cellular structure. Studies that definitively demonstrate

competence of tendon allografts in vivo are currently in

progress.

Adoption of SCCO2

sterilization by tissue banks will likely offer several

advantages, including the ability to perform terminal

sterilization in-house, preserve biomechanical properties of the

allograft, and reduce the need for microbiological

quantification of incoming bioburden. SCCO2 also makes possible

the use of industry standard validation methodologies, as with

medical devices, and possible eventual parametric release of

treated tissues. These advantages will facilitate continued

innovation and safe, high quality allografts by clearing

existing safety and biomechanical concerns associated with

current practices of tissue processing. Ultimately, the ability

to choose from a variety of sterilization options will increase

patient safety as well as positive surgical outcomes.

Reference :

-

United

States Bone and Joint Decade. Fast Facts on the Bone and

Joint Decade.

2006.

-

DePaula

CA, Truncale KG, Gertzman AA, Sunwoo MH, Dunn MG. Effects of

hydrogen peroxide cleaning procedures on bone graft

osteoinductivity and mechanical properties. Cell Tissue Bank

2005;6(4):287-98.

-

Arizono

T, Iwamoto Y, Okuyama K, Sugioka Y. Ethylene oxide

sterilization of bone grafts. Residual gas concentration and

fibroblast toxicity. Acta Orthop Scand 1994 Dec;65(6):640-2.

-

Thoren

K, Aspenberg P, Thorngren KG. Lipid extracted bank bone.

Bone conductive and mechanical properties. Clin Orthop Relat

Res 1995 Feb;(311):232-46.

-

Currey

JD, Brear K, Zioupos P, Reilly GC. Effect of formaldehyde

fixation on some mechanical properties of bovine bone.

Biomaterials 1995 Nov;16(16):1267-71.

-

Organ

Transplant and Grafts 1990 to 2009. Washington, DC: Census

Bureau; 2009. Report No.: 171.

-

Wang

S, Zinderman C, Wise R, Braun M. Infections and human tissue

transplants: review of FDA MedWatch reports 2001-2004. Cell

Tissue Bank 2007;8(3):211-9.

-

Akkus

O, Rimnac CM. Fracture resistance of gamma radiation

sterilized cortical bone allografts. J Orthop Res 2001

Sep;19(5):927-34.

-

Lomas

RJ, Gillan HL, Matthews JB, Ingham E, Kearney JN. An

evaluation of the capacity of differently prepared

demineralised bone matrices (DBM) and toxic residuals of

ethylene oxide (EtOx) to provoke an inflammatory response in

vitro. Biomaterials 2001 May;22(9):913-21.

-

Cornu

O, Banse X, Docquier PL, Luyckx S, Delloye C. Effect of

freeze-drying and gamma irradiation on the mechanical

properties of human cancellous bone. J Orthop Res 2000

May;18(3):426-31.

-

White

A, Burns D, Christensen TW. Effective terminal sterilization

using supercritical carbon dioxide. J Biotechnol 2006 Feb

20.

-

Fages

J, Poirier B, Barbier Y, Frayssinet P, Joffret ML, Majewski

W, et al. Viral inactivation of human bone tissue using

supercritical fluid extraction. ASAIO J 1998

Jul;44(4):289-93.

-

Fages

J, Poddevin N, King MW, Marois Y, Bronner J, Jakubiec B, et

al. Use of supercritical fluid extraction as a method of

cleaning anterior cruciate ligament prostheses: in vitro and

in vivo validation. ASAIO J 1998 Jul;44(4):278-88.

-

Lomas

R, Drummond O, Kearney JN. Processing of whole femoral head

allografts: a method for improving clinical efficacy and

safety. Cell Tissue Bank 2000;1(3):193-200.

-

Fages

J, Marty A, Delga C, Condoret JS, Combes D, Frayssinet P.

Use of supercritical CO2 for bone delipidation. Biomaterials

1994 Jul;15(9):650-6.

-

Kakiuchi

M, Ono K. Preparation of bank bone using defatting,

freeze-drying and sterilisation with ethylene oxide gas.

Part 2. Clinical evaluation of its efficacy and safety. Int

Orthop 1996;20(3):147-52.

-

Frayssinet

P, Rouquet N, Mathon D, Autefage A, Fages J. Histological

integration of allogeneic cancellous bone tissue treated by

supercritical CO2 implanted in sheep bones. Biomaterials

1998 Dec;19(24):2247-53.

|