|

Abstract:

Anodized

implant surfaces which exhibit surface parameters like

roughness, micro porosities etc are found to result in faster

bone formation around a metallic implant. Cell adhesion on to an

implant surface is found to be based on protein adhesion

molecules and these molecules are learnt to favor a more

hydrophobic surface. In this study Ti6Al4V implant material was

anodized to varying levels and cell adhesion to these surfaces

were studied by a 3-(4, 5-dimethylthiazol-2-yl)-2, 5-diphenyl

tetrazolium bromide (MTT) assay. The degree of influence of

surface wet ability on cell adhesion was compared with other

surface parameters like roughness, micro porosities etc. The

anodized Ti6Al4V sample which showed maximum hydrophobic nature

also exhibited higher surface roughness and porosities which are

favorable for osteoblast adhesion and showed highest cell

viability. However it was noted that the anodized samples with

lesser hydrophobic nature than even the control surface of plain

polished Ti6Al4V also exhibited good cell adhesion

characteristics in the cell viability studies. It was concluded

that even though protein adhesion molecules favor a more

hydrophobic anodized surface ,the other factors like surface

roughness and micro porosities of surfaces compensates for a

lesser hydrophobic anodized surface to give appreciable cell

adhesion.

J.Orthopaedics 2009;6(1)e5

Keywords:

Ti6Al4V; Anodization; MTT assay; cell

viability

Introduction:

Titanium

and its alloys are the materials of choice for most dental and

orthopedic implants due to its biocompatibility and excellent

mechanical properties [1-3]. Among the Titanium alloys TiAl6V4

(Ti) is the most commonly used implant material [1-3].

Bone response and tissue integration with the implant material

depends on the physical and chemical properties of the surface.

Different surface modification techniques have been developed

for increasing the surface properties of (Ti), anodization being one of them[4].It has been well

established that the adhesion of osteoblasts on to an implant

surface is by the interaction of cell adhesion protein molecules

and these molecules favor surfaces with comparatively lesser

wetability, higher roughness

and porosities [5-8]. Anodized surfaces exhibit these

characteristics but these parameters vary with varying degree of

anodization. In this study Ti samples have been acid anodized at

different voltages to varying degree of anodization and the

influence of their surface properties and contact angle

measurements were studied to assess their protein adhesion

characteristics as compared to a control surface as well as an

acid etched surface (deoxidized). The results have been

counterchecked using a cell viability study of osteoblast cells

on the surface by an MTT assay and confocal imaging.

Materials

and Methods:

Medical

grade Ti disks of 15 mm diameter and 2mm thickness were cleaned

ultrasonically in acetone for 20 minutes and later cleaned in

70% ethanol solution and washed with distilled water. The

samples were etched in knolls reagent (2ml HF (40%) and 4 ml HNO3

(66%) in 1000 ml of water) and rinsed in distilled water and

dried in air. One set of etched sample was used for comparative

studies.

2.1

Procedure for anodization [9-10]

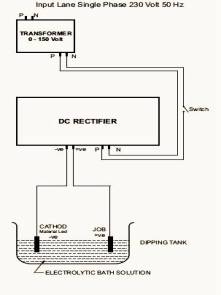

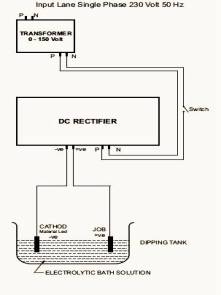

Set

up for anodization of the samples is shown in fig1.Ti was

anodized in 200 g/L sulfuric acid, 5% trisodium phosphate, and

5% sodium bicarbonate (baking soda). The electrolyte was

contained in a chemical resistant tank with Fume extraction. A

D.C. electrical supply with voltage regulation from 2 to

100 volts and sheet lead cathodes were provided.

|

| Fig 1: Set up

for anodization of the Ti samples |

The

parts to be treated was immersed in the processing solution and

connected as the anode to the electrical D.C. source. The

temperature of the bath was maintained in the range of 20- 26°C

throughout the duration of treatment.

The

cell voltage was varied between 50-75 volts and three anodized

samples were obtained at 55 volts with yellow surface appearance

(sample labelled as yellow),60 volts with pink surface

appearance (sample labelled as pink) and 75 volts with blue

surface appearance (sample labelled as blue) respectively . The

time of treatment was 15 minutes for each sample. Immediately

after removal from the anodizing bath, parts were washed

thoroughly in clean running water, rinsed in clean hot water and

allowed to dry.

2.2 Characterization of Ti samples [11]

2.2.1

Film Thickness

The

thickness

of the anodized surfaces and average roughness was measured

using a Veeco Dektak 6M stylus profilometer.

2.2.2 Surface Morphology

Surface

morphology of the samples was examined using Scanning Electron

Microscope (SEM) (Hitachi S-2500, Tokyo, Japan).

2.2.3

Contact angle measurement

The

contact angles of the samples with three different fluids were

measured using a NRL contact angle goniometer (USA)

using the sessile drop method

[12] in three well characterized liquids, water, formamide and

di-iodomethane as per previous studies [13].

2.3

Cell Viability studies

2.3.1

Cell Culture

Osteosarcoma

cell line KHOS-NP (R-970-5) [NCCS] were grown in culture medium

(DMEM+10%FBS+1mM NEAA) in a T-25 flask and incubated at 37oC

for 2 days in a 5% C02

incubator (Thermo). ~ 5x105cells

were plated on to three samples each of anodized, etched and

plain polished control samples of Ti in 12 well plates. The

culture was incubated for 72 hours at 37oC

in 5% CO2

incubator. The samples with attached cells were used for MTT

assay and confocal microscopy.

2.3.2

MTT assay [14]

For

MTT assay, all the samples were transferred to a fresh plate and

800 mL

of MTT reagent was added to each well and incubated for 2 hours

at 37OC.

MTT transformed to dark blue formazan by mitochondrial

dehydrogenises enabling cell viability to be assessed. 800 mL

of lysis buffer (20%Sodium Dodecyl Sulphate 50% Dimethyl

Formamide 30% Distilled water) was added to each well, mixed and

incubated at 37oC

for 4 hours. 200 mL

of each sample was transferred to a fresh 96 well plate and the

optical density of the solution was measured at 570nm in an

ELISA microplate reader (Biorad USA). Analysis of optical

variance was used to evaluate difference in cell viability

between the groups [15].

2.3.3

Confocal Imaging

Osteosarcoma

cells were grown on another set of anodized etched and control

Ti samples in culture medium for 48 hours.

After which the cells were fixed with 4% Paraformaldehyde

( PFA), washed twice in 1X Phosphate Buffered Saline (pH 7.4)

(PBS) and incubated in DAPI (4’, 6-Diamidino-2-phenyindole)

(1:1000) for 10 minutes at room temperature (280C).

Cells were imaged for nuclear visualization thereafter using a

confocal microscope (Leica TCS SPE Germany).

Results

and Discussion:

The

plots of contact angle for the various implant surfaces are

shown in fig 2. As can be seen the contact angle for the

anodized sample (blue) at 75 volts is the highest in all fluids,

whereas the samples anodized at lower voltages (pink and yellow)

have lesser or comparable contact angles to that of the control

sample as

Fig

2: Plot of contact angles of the various samples in different

mediums.

as

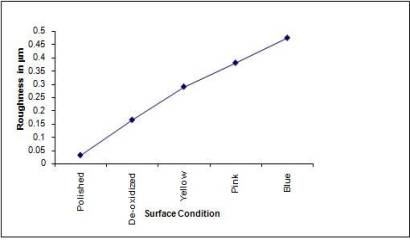

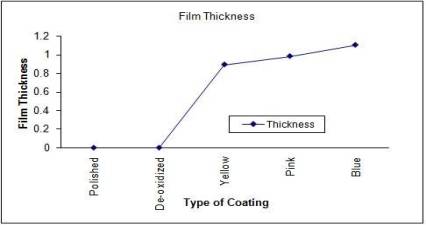

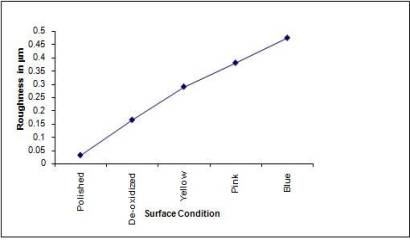

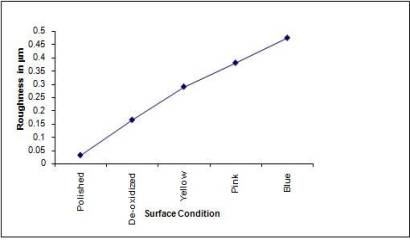

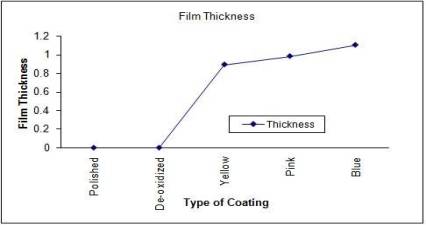

well as the etched (deoxidized) sample. The plot of surface

roughness and surface thickness of the samples are shown in fig

3 and fig 4. It is seen that the surface roughness and thickness

varies almost linearly with the degree of anodization.

Fig

3: Plot of average surface roughness of the various samples.

Fig

4: Plot of surface thickness of various samples

The

anodization thickness also increases linearly with the

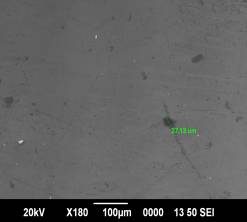

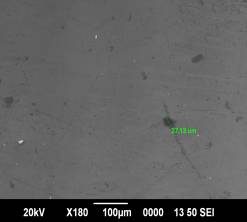

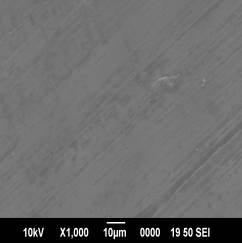

anodization voltages. The scanning electron micrographs of the

various surfaces are shown in fig5-8.The sample anodized at the

highest voltage of 75 volts exhibit highest micro-porosities and

surface asperities followed by the ones anodized at lower

voltages. Etched sample (deoxidized) shows distinct etch line

topography.

5 |

6 |

7 |

8 |

|

Fig 5-8:

SEM micrographs of anodized and etched samples 5. Ti

anodized at 75 volts, 6.Ti anodized at 60 volts, 7.Ti

anodized at 55 volts, 8.HF etched Ti.

|

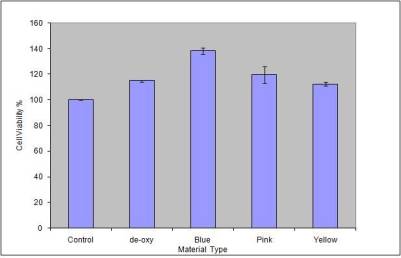

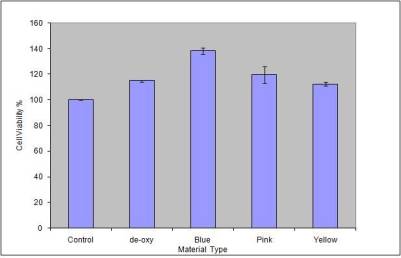

Variance analysis plot

for the different samples subjected to MTT assay is shown in fig

9.It is seen that the sample anodized at highest voltage of 75

volts (blue) exhibits maximum cell viability followed by the

sample anodized at lower voltages (pink and yellow) and the

etched (deoxidized) and control sample.

Fig

9: Optical variance analysis plot to assess the cell viability

of the samples

The confocal images of the

adhered nucleus to the various samples are shown in figs

10-14.

10 |

11 |

12 |

13 |

14 |

|

|

Fig 10-14:

Confocal Visualization of nuclear density on various

samples.Fig 10- Control TiAl6V4,Fig 11- Etched Sample,Fig

12- Anodized at 55V( Yellow),Fig 13-Anodized at 60

V(Pink),Fig 14-Anodized at 75 V(Blue). |

The

nuclear density as shown by the white patches is maximum for the

blue sample and decreases for the pink and yellow samples. The

etched sample showed nuclear density just lower than the pink

sample. The nucleus density confirms the maximum cell adhesion

characteristics of the sample anodized at 75 V followed by the

sample anodized at lower voltages and comparable nuclear density

for the etched sample to that of the pink sample. The cell

viability of the control sample is found to be the lowest.

As

made clear in previous studies, adhesion of cells on to

substrates occur through adhesion molecules which are proteins

[5-6] .These proteins favour adhesion to hydrophobic, rough and

porous surfaces. Since the Ti surface anodized at 75 V (blue)

exhibits highest hydrophobic nature, surface roughness and

maximum porosities, it presents the ideal condition for cell

adhesion and is established in the cell viability study. However

even though the wetability of the other anodized (pink and

yellow) and etched samples are only comparable or even less than

that of the plain polished control sample they exhibited higher

cell adhesion than the control sample. This can be attributed to

the higher roughness and porous natures of these samples in

relation with the control sample. Hence even though the adhesion

protein molecules which determine the adhesion characteristics

of cells on to an

implant surface is known to favour a hydrophobic surface ,the

other surface conditions like roughness, micro-porosities

,thickness are seen to override the dependence of cell adhesion

on hydrophobicity of an anodized implant surface.

Conclusions:

Ti

substrates were anodized to varying degrees and their surface

parameters for cell protein adhesion like wetability, roughness,

micro-porosity and thickness were studied and the influence of

wetability on cell adhesion was compared with the other surface

parameters thro a MTT assay and confocal imaging of adhered

nuclear density. An anodized surface which has the highest

hydrophobic nature also exhibited maximum roughness and porosity

and was seen to exhibit the highest cell adhesion

characteristics. However other anodized surfaces which exhibited

lesser hydrophobic nature than the control Ti surface also

exhibited good cell adhesion. This shows the dependence of cell

adhesion more on the surface parameters like roughness, micro

porosities and thickness within this range than on the

wetability of the surface. This factor can be considered for

selection of anodized implant material for orthopaedic use.

Further study is required to optimize for roughness and

hydrophobicity of anodized implant material.

Acknowledgements:

The

authors wish to place on record their gratitude to the various

research scholars of Indian Institute of Science, Bangalore,

India for having assisted in the contact angle measurements.

Special thanks to the research scholars of the Optoelectronics

laboratory of the Department of Physics Cochin University of

Science and Technology, Kerala, India and Rajiv Gandhi Centre

for Biotechnology Thiruvananthapuram, Kerala, India for

facilitating the various surface analyses. Timely advises and

suggestions given by Dr K.V.Menon, Amrita Institute of Medical

Science , Kerala, India and Dr H.K.Varma, Sree Chitra Thirunal

Institute of Medical Sciences Kerala, India are appreciated.

Reference :

-

C.F.Koch,

S.Johnson, D.Kumar, M.Jelinik, D.B.Chrisey, A.Doraiswamy, C.

Jin, R.J.Narayan, I.N.Mihailescu- Pulsed Laser Deposition of

Hydroxyapatite thin films. Materials Science &

Engineering C 27 (2007) 484-494.

-

Adriana

Bigi, Elis Boanini, Barbara Bracci, Alessandro

Facchini,Silvia Panzavolta,Francesco Segatti,Luigina Sturba-

Nanocrystalline hydroxyapatite coatings on titanium: a new

fast biomimetic method.. Biomaterials 26 (2005) 4085-4089.

-

C.K.Wang,

J.H.Chern Lin, C.P. Ju, H.C. Ong and R.P.H.Chang-Structural

characterization of pulsed laser deposited hydroxyapatite

film on titanium substrate. Biomaterials 18 (1997)

1331-1336.

-

Han-Jun

Oh, Jong-Ho Lee,Yonsoo Jeong,Young-Jig Kim,Choong-Soo Chi-

Microstructural characterization of biomedical titanium

oxide fabricated by electrochemical method. Surface and

Coatings Technology 198 (2005) 247-252.

-

G.Legeay

and F.Poncin-Epaillard Surface Engineering by coating of

Hydrophilic Layers: Bioadhesion and Biocontamination.

Adhesion –current research and application. , 2005 WILEY-VCH

GmbH & Co KGaA, Weinheim ISBN: 3-527-31263-3,175-188.

-

Kevin

Kendall –Molecular Adhesion and its Applications.2004

Kluwer Academic Publishers, New York, ISBN

0-306-46520-5,275-301.

-

S.R.Sousa,

M.A.Barbosa - Effect of Hydroxyapatite Thickness on Metal

Ion Release from Ti6Al4V Substrates .Biomaterials 17 (1996)

397-404

-

Despina

D. Deligianni , Nikoleta D.Katsala , Petros G. Koutsoukos ,

Yiannis F. Missirlis -Effect of Surface Roughness of

Hydroxyapatite on Human Bone Marrow Cell Adhesion,

Proliferation, Differentiation and Detachment. Biomaterials

22 (2001) 87-96.

-

J.Cl.Puippe-Surface

Treatments of Titanium implants. European Cells and

Materials Vol.5.Supl.1, (2003) 32-33. ISSN 1473-2262.

-

E.W.Russel

–Process specifications for Anodization of Titanium and

Titanium Alloys .Material Specification. Willsons Printers

(Leicester) Ltd London UK ISBN 0 11 470734 0.

-

P.S

Vanzillotta, G.A.Soares, I.N.Bastos, R.A.Simao, N.K.Kuromoto

- Potentialities of some surface characterization techniques

for the development of titanium biomedical alloys. Materials

Research, vol 7, no 3,437-444, 2004.

-

D

E Pacham- Handbook of Adhesion. John Wiley and Sons

Ltd, West susex, England. ISBN -13 978-0-471-80874-9, 79-85.

-

A.A.

Thorpe, Thomas G.Nevell, Simon A.Young, John Tsibouklis-Surface

Energy characteristics of poly (methylpropenoxyfluoroalkylsiloxane)

film structures. Applied surface science 136 (1998) 99-104.

-

Seunghan

Oh, Chiara Daraio, Li-Han Chen, Thomas R. Pisanic, Rita R.

Fin˜ ones, Sungho Jin - Significantly

accelerated osteoblast cell growth on aligned TiO2 nanotubes,

Wiley InterScience. DOI: 10.1002/jbm.a.30722

-

Jo-Young

Suh, Bong-Cheol Jang, Xiaolong Zhu, Joo L.Ong, Kyohan Kim-

Effect of hydrothermally treated anodic oxide films on

osteoblast attachment and proliferation. Biomaterials 24

(2003) 347-355.

|